The packaging

Guaranteed freshness, from the dairy to the table.

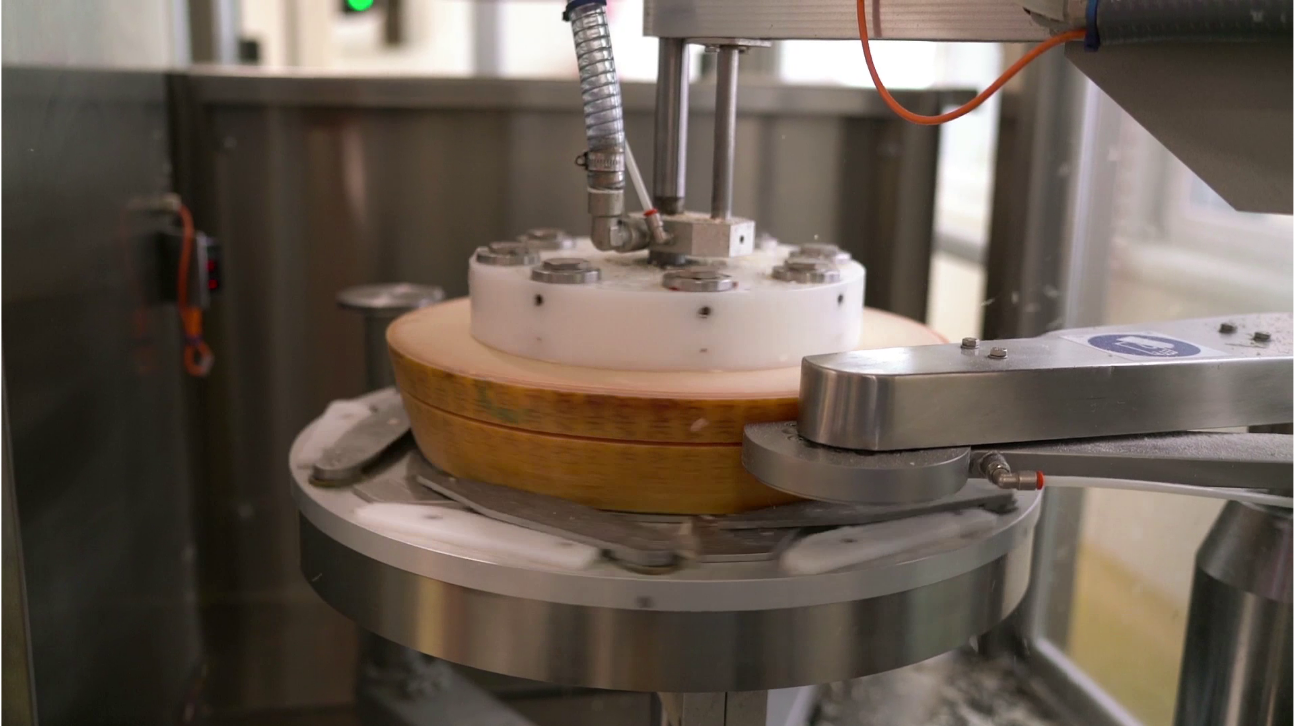

Producing milk and transforming it into organic Parmigiano Reggiano takes time and dedication. In order to avoid the risk of compromising the process, we decided to close the circle. That’s why the company inaugurated a modern packaging workshop next to its seasoning warehouse in 2015. We portion them out and package them directly in-house, with no need for the wheels to leave the company’s premises, thus eliminating the financial and environmental costs of transport. Automated and equipped with the food industry’s most reliable technologies, the packaging workshop is the last link in the production chain, which we now control in its entirety, and maintain at excellent quality standards.

In this manner, the product that we put on the consumer’s table is not only healthy and guaranteed, is but also dairy fresh.

We even portion out smaller sizes, with or without the rind (shaved, cubed, sticks and grated), which we pack both in modified atmospheres and in a vacuum.

The air inside the packaging room is purified and is maintained at a pressure greater than that outside, thus eliminating the possibility of contaminated outside air infiltrating the packaging room.